High Quality Chemical Materials TPE for PVC Pipe

- group name

- TPE

- Min Order

- 1 pack

- brand name

- XiZhou

- Nearest port for product export

- Shanghai, Lianyungang

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right

- update time

- Wed, 18 Oct 2017 09:41:52 GMT

Paramtents

HS Code 4002991100

Packging & Delivery

-

Min Order1 pack

Briefing

Detailed

| 1. | Description:a plastic rigid product modifier to achieve better plastification and anti-agglomeration performance |

2. Usage: PVC, Rubber, ABS, etc

3. Appearance: white powder

4. H.S.Code:3901909000

5.Package Forms: 25kg/bag, 550kg/bag, or as customers' requirements

Product Features:

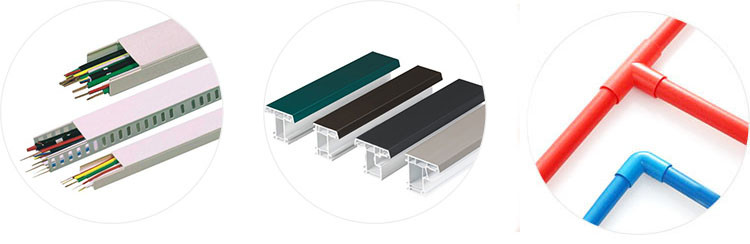

The material is safe and recyclable. It is environmental and friendly new materials. It not only has a soft touch, excellent

flexibility, but also has excellent coloring, excellent weather resistance and temperature performance. The material can

be processed by injection molding, extrusion, calendering and blow molding. It has excellent processing stability. It is

widely used in daily goods, sporting goods, toys, building materials, electronic appliances, auto parts and other fields.

BPK7590N is a styrene-based TPE. It has low odor, soft touch, smooth surface and excellent elasticity. BPK7590N is

the injection molding grade specifications for high-end products.

Product Features:

Items | Test | Unit | Value |

Shape | N/A | - | Granular |

Color | N/A | - | Origin Color |

Hardness | ASTM D-2240 | Shore/A | 75 |

Specific Gravity | ASTM D-792 | g/cm³ | 1.1 |

Melt Index @190℃/2.16kg | ASTM D-1238 | g/10min | 30 |

Tensile Strength | ASTM D-412 | Mpa | 5.7 |

Tear Strength | ASTM D-624 | N/mm | 41 |

Elongation at break | ASTM D-412 | % | 625 |

Molding Processing Guide:

Injection Molding Guide

Shrinkage: 0.015~0.025 inch/inch

Injection Speed: Medium ~High

Injection Pressure: Medium ~High

Back Pressure: Low ~Medium

Holding Pressure: Sufficient Product Film Shape

Cooling: Sufficient Product Cooling Stripping

Extrusion Processing Guide

Aspect Ratio: 20:1-25:1

Compression Ratio: 2.5-3.0

Plate and Filter: Need to Add Plate and Filter

Stretch: 5-10%

Cooling: Sink Cooling

Processing Attention:

A. Generally do not need to dry.if damp,it is recommended drying for 2-4 hours at 60℃.

B. It is advisable to clean the screw and die head with polypropylene or polyethylene before

processing the material.

C. Scraps can be reused.And it need to be dried before use.The amount is generally

not more than 15%. Its performance is basically good.

D. It is coloured with toner and color master batch.Using PE/EVA as the carrier of the master

batch can get a better color matching effect.

Raw Materials

The main raw materials HDPE are imported from Korea, SAMSUNG N220P; LG-CE6040

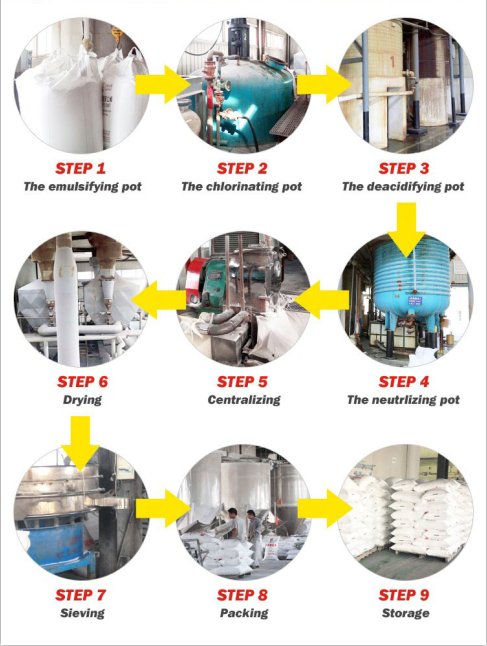

Production Flow

Workshop and Lab

1.Provide personalized customer's services;

2.Embrace flexibility and professionalism;

3.No lowest price but always value of money;

| 4. | Treat workers and other suppliers as respectful partners.in the past more than 10years,with high quality products and outstanding customer services,Jubang has gained a global sales network,covering Europe,USA,Southeast Asia,India,Africa and South American,etc. |

FAQ

<div style="line-height:24px;word-spacing:0px;font-size:16px;>

Q: What is the means of transport?

A: By ocean shipping, from Shanghai or Lianyungang port.

Q: Are you a factory or trading company?

A:we are a factory supplier for CPE 135A.There are international trade dept in factory and a trade company in WuXi city.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Suzhou city, Anhui Province. You can fly to Shanghai airport and take fast train to Suzhou directly. All our client, from home or aboard, are warmly ;welcome to visit us!

Q: How can I get samples?

A: We are honored to offer you CPE 135A samples free.

Q: How does your factory do regarding quality control?

A: Quality is our soul. We always attach great importance to quality control from the very begining to the very end. Our factory has gained SGS authentication. Every batch has its own test report.