What effects does CPE have on PVC products?

publisherKevin

time2016/06/13

- CPE is the abbreviation of “Chlorinated Polyethylene”, which is chlorinated from high-density polyethylene.

CPE is the abbreviation of “Chlorinated Polyethylene”, which is chlorinated from high-density polyethylene.

1. Application of CPE

As per different applications of CPE, it can be divided into 3 types, namely Type A, Type B and Type C. From Type A to Type C, the molecular weight of CPE decreases progressively.

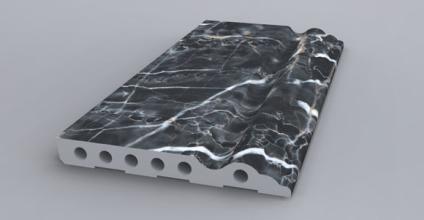

(1) CPE type A is mainly used as PVC impact modifier, as a kind of auxiliary agent.

(2) CPE type B is used in rubber industry as raw material to manufacture cable & wire protective cover and flexible tubes. It can also be used together with NR, NBR, CR, CSM and EPDM, etc.

(3) CPE type C is mainly used to modify ABS and injected PVC products like PVC pipe fittings.

2. Application of CPE in PVC industry, performance of PVC/CPE blend and ots influence factors

(1). PVC/CPE Blend

PVC/CPE blend has its own phase structure, which is macroscopic homogeneous phase and microscopic multiphase.

CPE must have a certain compatibility with PVC. There is no chemical bond between these two materials, but intermolecular force ( Van Der Waals force and hydrogen bonding). Phase structure is affected a lot by process conditions.

Most polymer blends are compatible with each other and have multi-phased structure.

Having microscopic or submicroscopic multi-phase structure is a critical condition that enables the blends to have good impact resistance.

(2). Morphostructure

A. Morphostructure of blends is determined by polymers’ property, blending method and blending process conditions.

B. Basic feature of blend’s morphostructure: one polymer (as dispersion phase) is dispersed into another polymer ( as dispersion medium or matrix); or two polymers co-exist in the form of connected continuous phase.

C. There is a transition zone, namely boundary layer between double phases of polymers, which plays an important role in the performance of blends.

(3). Boundary layer

A. Polymers’ blends have 3 domain structures: independent phases of two polymers and boundary layer between such phases.

B. Boundary layer is also called transition zone where cohesion and mutual dispersion of two polymers happen.

C. The structure of boundary layer, especially adhesive strength between two polymers, may put decisive effect on the performance of blends, especially mechanical property.

with the increase of compatibility bwtweenpolymers

↓

dispersion rate increasing

↓

boundary between phases blurring

↓

the thickness of boundary layer increasing

↓

adhesive force between phases increasing

↓

mechanical property of PVC/CPE blend increasing